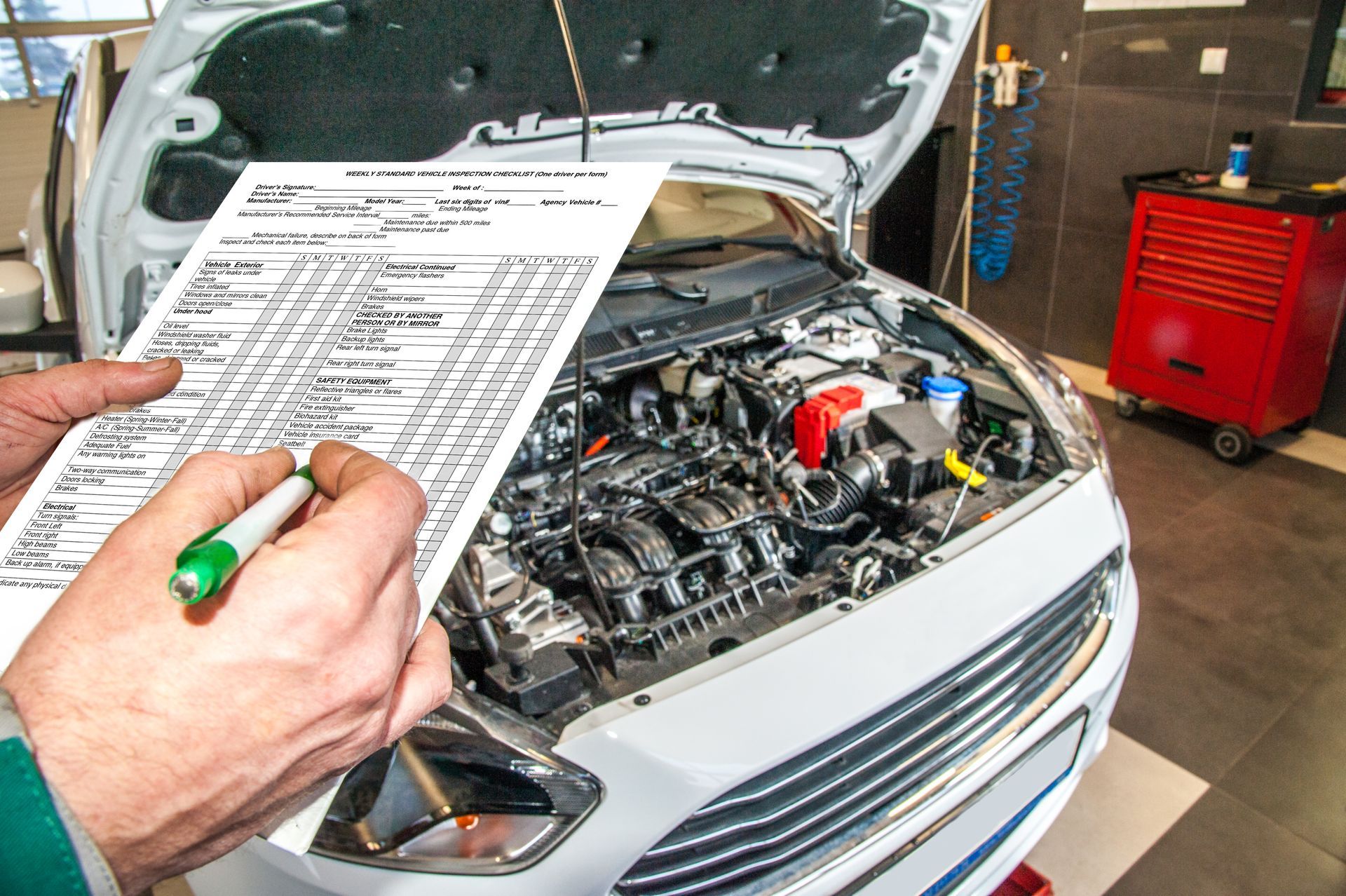

A good Ford pickup is built to work, but even a tough truck will start to complain if maintenance only happens when something breaks. Hot summers, heavy towing, dusty roads, and sudden cold snaps all put stress on different systems at different times of the year. Staying ahead of that wear is less about fancy upgrades and more about doing the basics on time and paying attention when the truck sends you early warning signs.

Why Ford Pickups Need Consistent Maintenance

Pickup trucks usually live a harder life than small cars. They haul trailers, carry tools, sit idling on job sites, and see more dirt and gravel roads. All of that means more heat in the engine and transmission, more weight on the suspension, and more cycles on the brakes.

Over time, fluid breakdown, bushing wear, and small leaks can turn into hard starting, harsh shifting, or vague steering. Regular checks keep those small issues from becoming big ones. From the shop side, we often see that the most reliable trucks are not the ones with the lightest duty, but the ones that get consistent, basic care.

Engine and Fluids: Heat, Towing, and Stop-and-Go Traffic

Engines in trucks often run under heavier load, even if you are just commuting with a bed full of gear. Oil has to cope with heat, dust, and sometimes long idle time with the air conditioning on. Sticking to a realistic oil change interval for your driving, rather than the absolute maximum number in the manual, helps the engine stay clean inside.

Coolant condition matters just as much. Old coolant loses its corrosion protection and can let scale build up in radiators and heater cores. That shows up as subtle temperature swings, weak cabin heat in winter, or rising temps on long grades. Transmission and differential fluids see extra stress any time you tow, haul, or climb, so having those checked and serviced on schedule is a key part of keeping a Ford truck smooth and dependable.

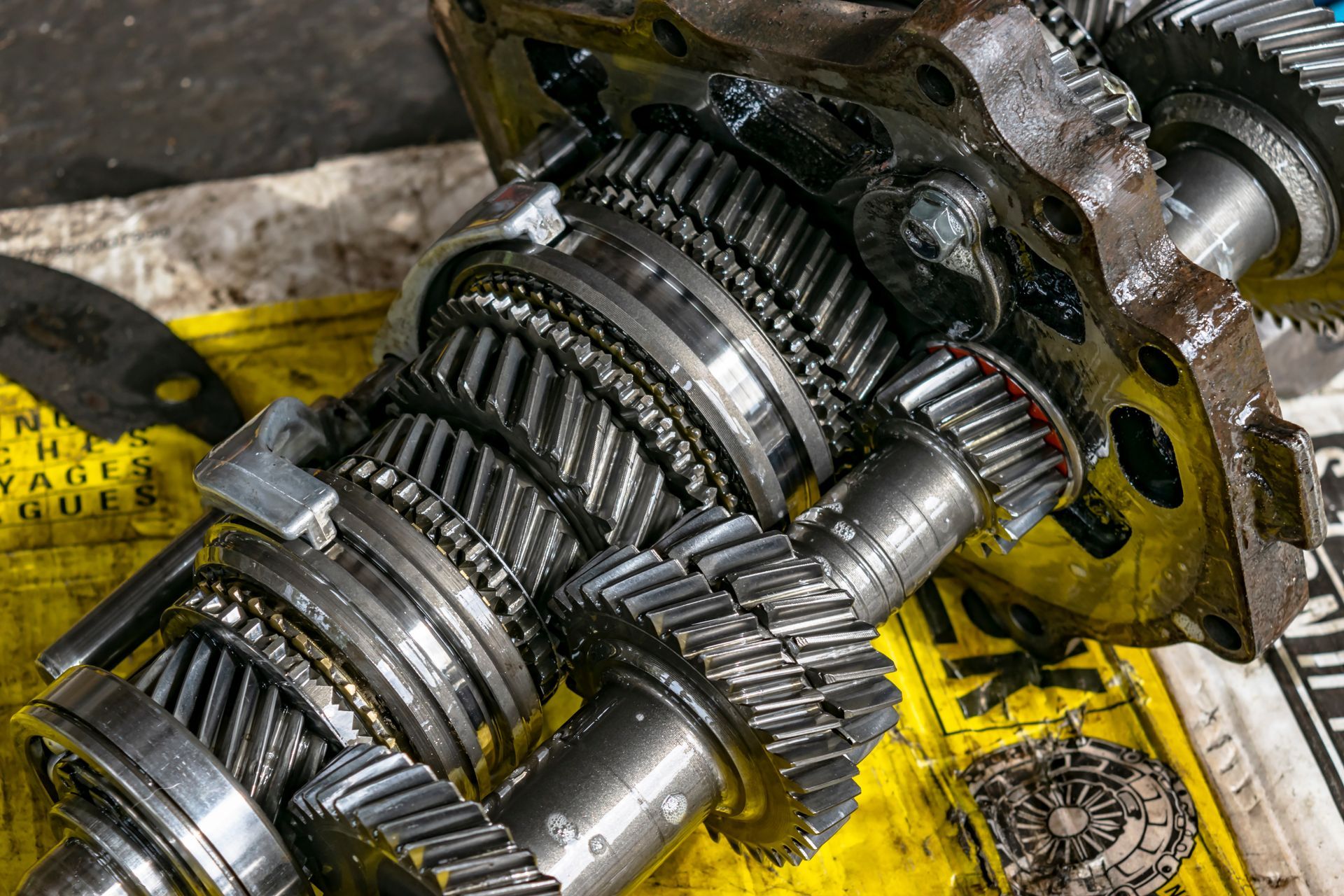

Protecting Drivetrain and Axles Under Load

The drivetrain in a pickup is designed for work, but it will still wear out early if it is never checked. Simple, regular inspections go a long way:

- Look for seepage around differential covers, pinion seals, and axle shafts

- Listen for humming or howling that changes with road speed, not engine speed

- Pay attention to clunks when shifting from Drive to Reverse or when taking off

- Check for vibration during towing that was not there when the truck was empty

- Make sure four wheel drive engages and disengages cleanly before you need it

Catching a small gear oil leak or early u-joint play is much cheaper than waiting until a differential or driveshaft fails under load.

Suspension, Steering, and Brakes on Rough Texas Roads

Potholes, expansion joints, washboard roads, and job site entrances all beat up suspension parts. Ball joints, control arm bushings, tie rods, and leaf spring components slowly loosen over time. The truck might still track straight, but you may notice more wandering in crosswinds, extra steering correction on the highway, or clunks over small bumps.

Brakes deal with truck weight, trailers, and heat from long stops. If you feel vibration in the steering wheel under braking, hear grinding, or notice the pedal getting softer over a few months, it is time for a close look. A good year-round plan is to have suspension and brakes inspected at the same time as tire rotations, so you can spot uneven wear or loose parts before they affect safety.

Electrical System and Battery Checks Through the Seasons

Modern pickups have powerful electrical systems that run far more than just lights and a radio. Plows, light bars, inverters, and trailer brakes all draw current, and that load changes with the season. A battery that seems fine in mild weather can struggle when the temperature drops or when you run a lot of accessories.

It helps to keep up with a few simple checks:

- Inspect battery terminals for corrosion and clean them before it builds up

- Have the battery load tested yearly once it is past the three year mark

- Verify the alternator output if you notice dimming lights at idle with accessories on

- Check trailer wiring for corrosion and loose connections before towing season

- Pay attention to slow cranking or intermittent warning lights, rather than ignoring them

Finding a weak battery or poor ground in the shop beats dealing with a truck that will not crank on a hot or cold morning.

Simple Driver Habits That Keep Your Truck Reliable

How you use the truck between services matters as much as what happens during an oil change. Letting the engine warm up gently before heavy throttle, especially after a cold start, reduces wear. Giving the transmission a moment to engage before pulling away with a heavy trailer takes stress off the clutches and mounts.

Washing the truck regularly, including the frame and wheel wells, helps slow down rust on brake lines, brackets, and suspension hardware. Listening for new noises, feeling for changes in steering, and watching for small drips on the driveway all give you early hints that something needs attention. When owners bring those little changes to us early, repairs are usually smaller, cheaper, and quicker to handle.

Get Year-Round Ford Truck Maintenance in Texas with Yes! Automotive

We work on Ford pickups every day and know how heat, towing, and daily use affect their engines, drivetrains, and suspensions over time. We can set up a maintenance plan around how you actually use your truck, so small issues are caught before they turn into breakdowns.

Call Yes! Automotive in Texas to schedule year-round Ford truck maintenance and keep your pickup ready for work or weekend trips in any season.

- Yes! Automotive - Porter, 24608 TX-494 Loop, Porter, TX

- Yes! Automotive - Highway 6, 5608 Highway 6 North, Houston, TX

- Yes! Automotive - Spring, 3443 Farm to Market 2920, Spring, TX

- Yes! Automotive – Pinehurst, 31426 Texas 249, Pinehurst, TX